Just how to Select the Right Opel Corsa Engine for Your Automobile

Just how to Select the Right Opel Corsa Engine for Your Automobile

Blog Article

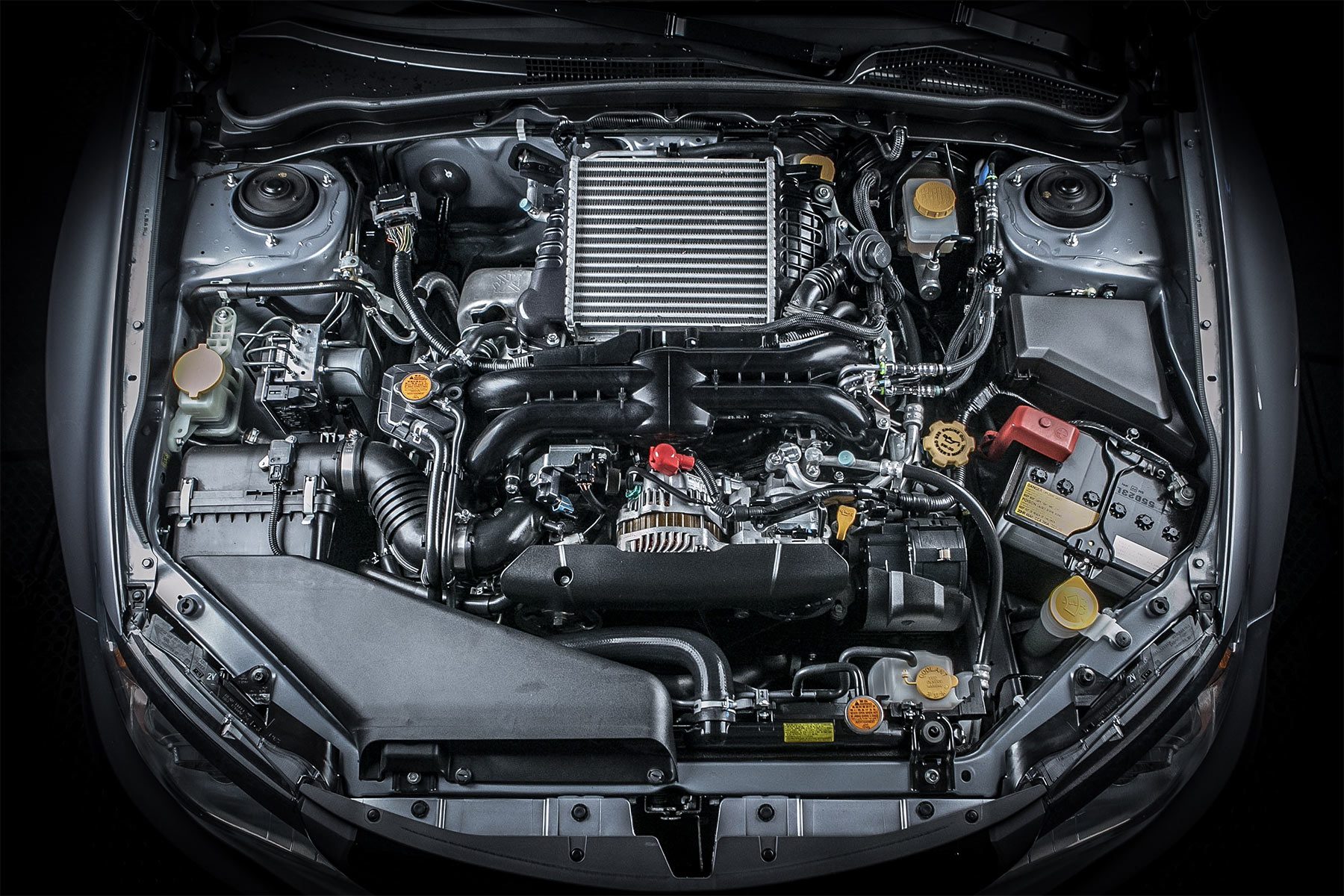

Checking Out the Inner Functions of a Compact Vehicle's Engine System

As vehicle drivers, we typically take for granted the intricate processes that take place within the boundaries of our vehicle's engine system. In this expedition of a portable car's engine system, we will certainly unravel the inner workings of this mechanical harmony, dropping light on the enigmas that drive us ahead on our daily journeys.

Combustion Process Review

The combustion process in a portable vehicle's engine system is an important mechanism that effectively transforms fuel right into energy to power the automobile. This procedure takes place within the burning chamber of the engine, where gas and air mix, ignite, and generate regulated explosions. The burning procedure consists of four main stages: consumption, compression, exhaust, and power.

During the consumption stage, the piston moves downward, reeling in a blend of air and fuel right into the combustion chamber. The following phase, compression, entails the piston moving upward, pressing the air-fuel mix to increase its potency. Subsequently, in the power phase, the trigger plug ignites the compressed blend, causing a fast expansion of gases that requires the piston back down. This downward movement produces the power needed to drive the lorry. Finally, in the exhaust stage, the burned gases are eliminated from the combustion chamber through the exhaust valve, preparing the chamber for the next cycle. This cyclic burning process is basic to the procedure of a small vehicle's engine system, making sure effective power conversion for propulsion.

Piston and Cylinder Interaction

The piston's specific fit within the cyndrical tube is important for preserving ideal compression and protecting against energy loss during combustion. Limited clearances in between the piston and cylinder wall surfaces make sure effective sealing, enabling the piston to move smoothly without allowing gases to leak past. Correct lubrication is additionally crucial to decrease friction and put on in between these elements, boosting long life and efficiency.

Moreover, the design and materials made use of in producing the piston and cyndrical tube impact engine effectiveness and resilience. Modern engines typically use lightweight yet sturdy products like aluminum alloys for pistons and cyndrical tube liners to reduce inertia and improve thermal performance. In general, the harmonious communication between the piston and cylinder is fundamental to the engine's capability and total efficiency.

Gas Shot System Capability

Gas injection systems in compact automobile engines play a crucial duty in precisely providing fuel to the combustion chamber for controlled and efficient ignition. The navigate to this website gas injection system functions by infusing gas into the burning chamber at the optimal minute during the engine's procedure (opel corsa engine). This precise timing makes sure that the fuel blends uniformly with the air for appropriate combustion, causing enhanced gas efficiency and minimized emissions

There are primarily 2 types of fuel shot systems used in small car engines: port gas shot (PFI) and direct gas injection (DFI) PFI systems infuse fuel right into the consumption port prior to the intake shutoff, while DFI systems inject fuel straight right into the combustion chamber. Both systems have their advantages, with DFI supplying far better fuel atomization and PFI offering a more economical remedy.

Comprehending Engine Cooling Devices

Efficient operation of a compact car's engine depends heavily on the performance of its cooling mechanisms. The cooling system in a small lorry typically consists of a number of parts functioning with each other to manage the engine temperature. Comprehending these engine cooling devices is essential for preserving the performance and long life of a compact vehicle's engine system.

Exhaust System Elements Explained

The optimum performance of a compact car's engine cooling systems depends on a corresponding system recognized as the exhaust system, which consists of numerous essential components for guaranteeing effective discharges and engine performance. The exhaust manifold gathers exhaust gases from the engine's courses and cylinders them to the catalytic converter.

One crucial part of the exhaust system is the oxygen sensing unit, which checks the oxygen degrees in the exhaust gases to aid control fuel consumption and ensure ideal engine helpful hints performance. opel corsa engine. Furthermore, the resonator may exist in some exhaust systems to lower sound degrees. Overall, the exhaust system plays a crucial role in keeping engine performance, decreasing unsafe discharges, and making sure a quieter driving experience for small car proprietors

Final Thought

Finally, the portable vehicle's engine system is an intricate combination of components that interact to assist in the combustion procedure, transform fuel right into energy, and expel waste gases. Comprehending the inner functions of the engine system, consisting of the piston and cyndrical tube interaction, gas injection system, engine cooling mechanisms, and exhaust system components, is crucial for preserving ideal performance and performance of pop over to this web-site the vehicle.

The combustion procedure in a small automobile's engine system is an essential device that efficiently converts fuel into power to power the automobile.Fuel injection systems in compact automobile engines play an essential role in precisely supplying gas to the combustion chamber for regulated and efficient ignition.There are primarily two types of fuel injection systems made use of in small vehicle engines: port fuel injection (PFI) and direct gas shot (DFI) Comprehending these engine air conditioning mechanisms is important for maintaining the performance and long life of a small automobile's engine system.

The optimal functioning of a compact vehicle's engine cooling mechanisms depends on a complementary system understood as the exhaust system, which consists of different vital components for making sure efficient exhausts and engine performance.

Report this page